Capabilities & Instrumentation

Testing Capabilities

- Temperature Controlled Operation.

- Complete Optical Access supporting various Flow Visualization and Optical Flow Diagnostic techniques.

- Fully Automated 4-Degree of Freedom Traversing System for model/instruments positioning.

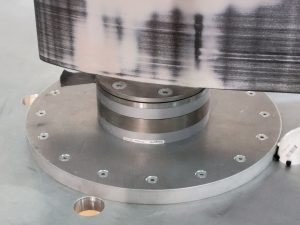

- Automated Turntable for model positioning.

- Whole-Field 3D-3C Flow Velocimetry.

- High Speed Data Acquisition.

- High Speed 3-Component Anemometry.

- Static & Dynamic Direct Force Measurement.

Facility Instrumentation

|

|

|

|

|

|

- Optical Particle Counters deliver high-quality particle counts and sizing and provide digital outputs of PM1, PM2.5 and PM10 (and optionally PM4.25) along with histograms of the particle count for each size. (Source: Alphasense Website)

|

|

|

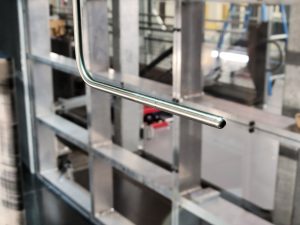

- A Hotwire anemometer is an instrument for measuring fluid velocity, whether it be of gases or fluids, hot wire or hot film. Hotwire Anemometers measure fluid speed using a delicate probe made of thin tungsten/platinum wire, or a thin metallic film. This probe is heated to a temperature higher than average temperature of the fluid. Using sophisticated circuitry, the anemometer stabilizes and maintains the probe temperature at a constant level throughout the measurement. Since the fluid flowing past the probe has a lower temperature than the probe, the film/wire is constantly being cooled by the fluid flow. The higher the velocity, the faster the rate of cooling. Since the anemometer must maintain the probe temperature at a constant level, it is therefore sensitive to the rate at which it is being cooled, i.e., the fluid velocity. (Source: A.A. Lab System Website)

- The A.A. Lab Systems Hotwire Anemometry System is capable of measuring 4 simultaneous channels (3 heated channels, 1 cold channel) and is equipped with an automatic probe calibrator with roll-pitch manipulator.

|

|

- The Cobra Probe from TurbulentFlow Instrumentation is a multi-hole pressure probe able to resolve 3-components of velocity and local static pressure in real time. A frequency response of 3 kHz means the Cobra Probe is especially suited to the measurement of turbulent flows, although accurate mean-flow measurements are also made. (Source:TFI Website)

|

|

|

- In Particle Image Velocimetry (PIV) light scattering particles are added to the flow. A laser beam is formed into a light sheet illuminating seeding particles twice with a short time interval Δt. In 2D-PIV the scattered light is recorded onto two consecutive frames of a high-resolution digital camera. In Stereo-PIV two cameras at different observation angles are used to measure also the third (out-of-plane) component of the flow velocity in the light sheet. (Source: LaVision Website)

- LaVision’s FlowMaster PIV systems can be used for 2D and stereoscopic flow field analysis. FlowMaster 2D measures two velocity components in a plane (2D2C) with one camera. FlowMaster Stereo-PIV is a straightforward extension of the FlowMaster 2D concept and enables the measurement of all three velocity components inside a light sheet (2D3C) using two cameras. (Source: LaVision Website)

- This setup includes two 6MP sCMOS 16-bit cameras, two 22MP CCD 12-bit cameras, a 380mJ dual-cavity laser and a dual-plane calibration target.

|

|

|

- The ATI 6-Axis Force/Torque Sensor system measures all six components of force and torque. The system consists of a transducer, shielded high-flex cable, and intelligent data acquisition system. Force/Torque sensors are used throughout industry for product testing, robotic assembly, grinding and polishing. In research, our sensors are used in robotic surgery, haptics, rehabilitation, neurology, and many other applications. (Source: ATI Website)

|

|

- High-magnification shadow Imaging is very suitable for visualizing particles, droplets, and other structures. The technique is based on high resolution imaging with pulsed backlight illumination. The measurement volume is defined by the focal plane and the depth of field of the imaging system. This technique is independent of the shape and material (either transparent or opaque) of the particles and allows the investigation of sizes down to the micro scale using an appropriate optical system. (Source: LaVision Website)

- High resolution imaging and special backlight illumination are the key components of the LaVision ParticleMaster Shadow system. As opposed to laser diffraction or interferometric methods shadowgraphy does not require transparent and spherical particles and, therefore, is a quite universal technique for comprehensive particle characterization. The ParticleMaster software package automatically identifies valid particles in an image series and calculates all particle properties with outstanding processing speed incl. statistical information in real-time. (Source: LaVision Website)

|

|

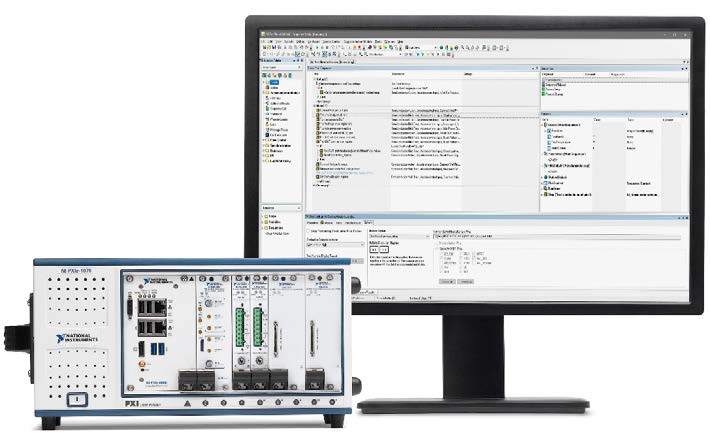

- The National Instrument PXI Express System with a maximum of 8 GB/s system bandwidth and an integrated controller combines a high-performance 8-slot PXI Express backplane with a high-output power supply and a structural design that has been optimized for maximum usability in a wide range of applications, without the need for an external PC. (Source: National Instrument Website)